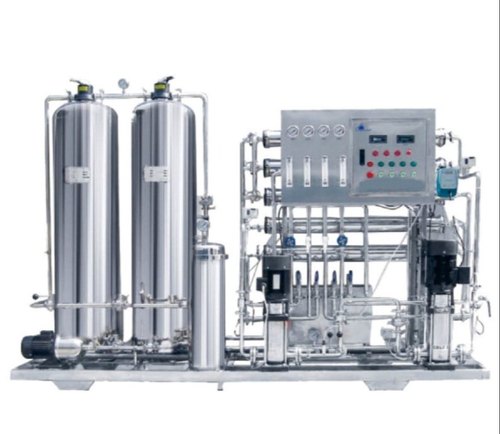

Choosing the right SS RO plant is an important aspect of choosing the right water treatment system for your needs. Not all manufacturers have the same quality and efficiency when making RO plants, and we are able to process the highest quality of water for high-end uses. They are able to meet the needs of different types of businesses and industries and are equipped with all the necessary equipment for this.

Whether you're running a small business or a huge corporation, we, as a Stainless Steel SS RO Plant Manufacturer and supplier, is integral to your overall water supply. These plants not only purify water but also filter the water, which makes the water more healthy, reducing your health concerns. We right SS RO Plants Manufacturer and supplier for you to ensure that your water is crystal-clear and free from harmful chemicals.

A Stainless Steel SS RO Plant Manufacturer and supplier has a variety of options for its customers. Their filtration systems are designed to make the process as simple as possible for the customer. A 500 lph SS RO Plant from an SS RO Plants Manufacturer and supplier will cost you around Rs 90,000. The benefits of a reputable SS RO Plant supplier are numerous and will provide you with quality water for high-end uses.

As an SS RO Plants manufacturer and supplier based in Delhi and Mumbai, we produce top-quality products. We are competitive and safely process water. As a result, our production meets the highest standards. We also provide customized solutions for the different needs of our clients. In this way, we can ensure the quality of the products. We are proud to offer our products at the most competitive prices.

Our RO plants are crafted to provide convenience to the customers. We offer RO plants with capacities ranging from 100 LPH to 20,000 LPH. They are easy to install and are highly efficient. We use premium raw materials for them and design them by professionals, to deliver the best quality product. Our systems are also designed to be user-friendly, allowing you to operate them from anywhere using a smartphone easily.

SS RO Plants are manufactured for commercial use and are available in a wide range of capacities. These SS RO Plants are made to cater to the needs of various industries, and they are cost-effective and are designed for high-end use.

To know commercial RO water purifier or water treatment plant price or more about us, please Contact Us For Free Quotation.

There are several ways to get the most benefits from your commercial reverse osmosis RO plant. These include choosing a system that can process large amounts of water and a unit that is easy to maintain. The first way is to find a larger output capacity unit, which is important if you plan to sell the water to other businesses.

Alternatively, you can upgrade the membranes on your current system to a higher quality one. When purchasing a commercial reverse osmosis RO plant, make sure you understand the water quality requirements of your business. Some systems may need pre-treatment of the raw feed water. For example, a system that does not treat hard water or have a high hardness level will need an anti-scale chemical injection unit. Similarly, a system that processes water that is high in iron, manganese, or sulfide will need an oxidation unit.

If you have hard water, you may want to invest in a pre-treatment unit. Almost all commercial RO systems will require pre-treatment, and a water softener or anti-scale injection will be necessary to handle the water. Other water quality issues may require an oxidation unit. You can find these systems easily online, and they also have an easy-to-access design. Most come with a 1-year manufacturer's warranty.

Industrial stainless steel Reverse Osmosis RO Plants are the ideal solution for water and wastewater filtration. They are fabricated with high rejection TFC membrane elements, resulting in the highest possible yield and efficiency ratio. The resulting permeate is free from salts, and the feed stream can be used again. A high recovery rate means lower water costs and reduced waste. The yield of an industrial stainless steel Reverse Osmosis RO plant is a critical consideration.

Industrial stainless steel Reverse Osmosis RO Plants are highly reliable and easy to operate, and these plants can be customized to meet the specific requirements of your industrial process. These systems feature a multimedia prefilter, an antiscalant dosing system, and ultraviolet sterilization. The unit's control system is comprised of a programmable logic controller and an optional remote Windows-based operator station. Most industrial-grade RO systems start and stop automatically based on feed water tank levels.

An industrial reverse osmosis plant is equipped with a multi-stage prefilter, water softener, and a post-chlorination system. The machine transports feed water through the multimedia prefilter, which removes all particles larger than 10 microns. The prefilter also contains an antiscalant chemical, which is needed to prevent the membrane from fouling. The feed water goes through a second water stream, which is partially permeable and thus, is called a cross-flow osmosis.

Flow Range: 100 LPH to 100 KLPH (100m3)

Materials: Fiber Reinforced Plastic (FRP) / Stainless Steel (SS) / Mild Steel Rubber, Epoxy Lining (MSRL/MSEL)

Operation: Semi - automatic / fully automatic plants, Dashboard, Reporting and Analytics (DAR) for managing multi plant operations using Mobile, Laptop, and Tablets.

If you are interested in buying a stainless steel reverse osmosis RO plant for your home, you must know the following specifications. Firstly, the raw feed water must be treated before using the reverse osmosis system. If the hardness of the water is greater than 15 grains, you will need to install a water softener or anti-scale system. Other water quality problems like high levels of iron, manganese or sulfide will also require you to install an oxidation unit. The oxidation unit can also be installed in some systems.

Industrial RO systems usually include multiple stages of polycarbonate diffusers, multimedia prefilters, and ultraviolet sterilizers. The main unit of an industrial RO system transports feed water through a multi-stage filter. The media filters remove contaminants that are larger than 10 microns. After passing through the membranes, the feed water is injected with anti-scalant chemicals. The anti-scalant chemical is injected into the feed water to control the hardness fouling in the system.

In industrial settings, the output of a reverse osmosis system depends on water pressure, water temperature, and water conditions. The industry standard input temperature is 77 degrees Fahrenheit. To calculate the output, you can refer to a water temperature compensation chart and multiply the GPD of your system by the temperature factor. When calculating your GPD, you need to consider the pressure of the feed and the pressure of the water. The higher the pressure, the higher the output.